Closed Reactor

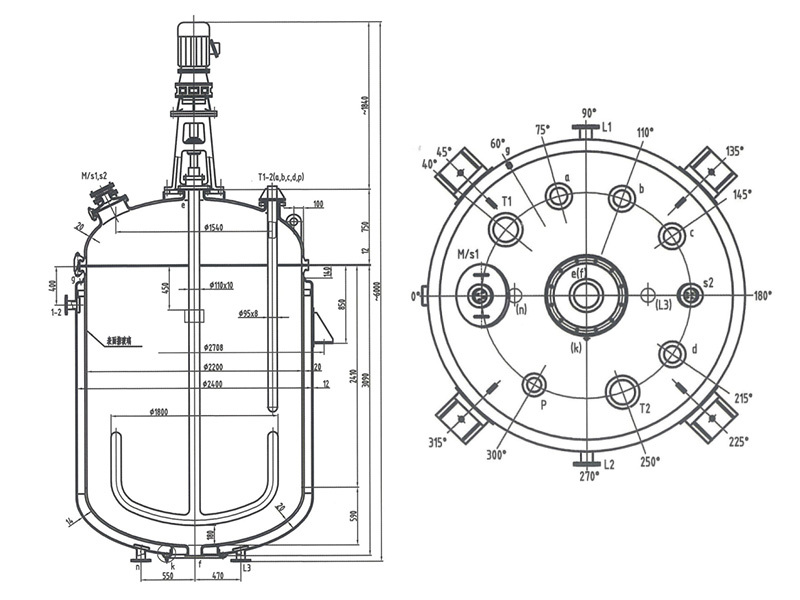

K10000L glass-lined reaction tank design drawing

Graphic Details

K10000L glass-lined reaction tank design drawing:

Main technical parameters of K10000L glass-lined reaction tank

|

Parameter table |

In device |

Inner jacket |

|||

|

Total area m3 |

12.4 |

||||

|

Heat exchange area m2 |

|

21.8 |

|||

|

Design pressure Mpa |

0.4 |

0.6 |

|||

|

Design temperature°C |

200 |

200 |

|||

|

Steel plate material |

245R |

Q235B |

|||

|

Reference weight Kg |

7920 (excluding transmission equipment) |

||||

|

High voltage test (kv) |

20 |

||||

| Reducer-helical gear |

BF107 |

BF97 |

|||

|

Motor-Asynchronous explosion-proof KW |

YB11 |

||||

|

Rack |

DJ90 |

||||

|

Blender |

Anchor, box: |

Pulp, impeller: |

|||

|

Use media |

Resistant to corrosion by various concentrations of inorganic acids, organic acids, organic solvents and weak alkalis (hydrofluoric acid, media containing fluoride ions, concentration > 30% , Temperature> Except for 180% concentrated phosphoric acid and strong alkali) |

||||

|

Note: When the operating temperature is less than 0°C or the design pressure is greater than 0.4, it should be specified when ordering |

|||||

|

IV nozzle table |

|||||

|

symbol |

Nominal size |

Connecting flange standards |

Purpose |

||

|

M/sl |

400x300/125 |

|

Manhole (with sight glass) |

||

|

a |

DN150-B |

PNO. 6HG/T2105-2006 |

Backup port |

||

|

b |

DN150-B |

PNO. 6HG/T2105-2006 |

Backup port |

||

|

c |

DN150-B |

PNO. 6HG/T2105-2006 |

Backup port |

||

|

d |

DN150-B |

PNO. 6HG/T2105-2006 |

alignment |

||

|

e |

DN200-A |

PNO. 6HG/T2105-2006 |

align orientation |

||

|

f |

DN150-A |

PNO. 6HG/T2105-2006 |

right side |

||

|

p |

DN125-B |

PNO. 6HG/T2105-2006 |

slope alignment |

||

|

s2 |

DN125-A |

|

Chapter |

||

|

T1~2 |

DN200-B |

PNO. 6HG/T2105-2006 |

center(center) |

||

|

L1~3 |

DN80 |

PL80 (B) -10RF |

center(center) |

||

|

n |

DN80 |

PL80 (B) -10RF |

alignment |

||

|

g |

G3/4" |

|

alignment |

||

|

h |

G1/2" |

|

alignment |

||